Amélie Photography

8509 Davis Blvd. North Richland Hills, TX 76182

Wood Furniture Buyer’s Guide

Wood Furniture Buyer’s Guide

At Woodbine Furniture Company, we understand that shopping for quality wood furniture can get confusing. So we developed this buyer’s guide to give you the knowledge you need to shop with confidence. We encourage you to use it when you compare our product with the products of our competitors. When you do, we believe you’ll find our Simply Amish Furniture provides superior quality and excellent value.

Materials Used In The Construction Of Furniture

Today’s wood furniture can be constructed of materials ranging from hardwood to softwood, particle board to plastic laminate, even synthetic molded resins designed to look like real wood. One of the keys to buying quality furniture, therefore, is recognizing the various materials available and understanding the differences between them.

Solid Wood And Wood Veneer

Perhaps the two most common terms you’ll hear in better quality wood furniture stores are “solid wood” and “wood veneer”. Most quality wood furniture is constructed of both, so a good understanding of what the terms mean is important.

Solid wood usually means most or all exposed parts of a piece of furniture are constructed of solid planks of wood, while the backs and shelves are typically veneer. Solid wood, especially hardwood, wears well, can be refinished, and lasts for generations if properly cared for.

Wood veneer is simply a thin sheet of wood glued on top of a “carrier” substrate such as plywood, particle board, or Masonite. The quality of the veneer is directly related to the quality of the substrate. In other words, plywood veneer is much higher quality, and is therefore more expensive, than particle board or Masonite veneers. In fact, some plywood veneers are so well made they are nearly indistinguishable from solid wood.

Veneer Or Solid?

To determine if a piece is constructed of veneer or solid wood, simply look in the direction of the wood grain. If the grain directions are not parallel, chances are the piece is veneer. You can also follow the wood grain to an edge. Look at the edge from the end; solid wood furniture will display internal wood grain. If the end grain is not visible, the piece is likely veneer.

In addition, these veneers possess some advantages over solid wood. They’re typically less expensive, more stable, and are less likely to warp. A quality plywood shelf, for instance, is often better for holding heavy items like books or a television than a comparable piece of solid wood. However, plywood cannot easily be refinished and is usually not as attractive as solid wood, so limiting its use to shelving and backing is preferable. See Section III below for more information on plywood veneer.

Hardwoods And Softwoods

Softwoods are less durable than hardwoods and more plentiful, in part, because the trees grow much quicker. They’re also less expensive and represent a better alternative than particle or fiber board. Common softwoods include pine, fir, spruce, and cedar.

Hardwoods are found in higher quality furniture and are prized for their durability and fine finishing qualities. Among the numerous hardwoods available today, our Amish craftsmen use primarily northern, slow-growth wood, chosen for the greater density typical of wood grown in colder climates. These woods make an excellent choice for buyers looking for American products or for those concerned about rainforest depletion. American hardwoods are a renewable resource and are not endangered species. Our craftsmen offer you a choice of seven North American hardwoods: red oak, white oak, soft maple, hard maple, cherry, hickory, and walnut.

Red Oak Quercas rubra

Red oak is a widely available and popular hardwood, chosen for its traditional, coarse-textured look and excellent durability and strength. It accepts stain consistently and wears very well, making red oak a good choice for furniture that will see everyday use. Natural color varies from yellow to pale brown, often with a light reddish tinge.

White Oak Quercas alba

Like red oak, white oak is hard, strong, and has outstanding wear-resistance. It has a medium-coarse to coarse texture and varies in color from light tan to nearly white or light grey. Our Amish craftsmen use quartersawn white oak for a unique aesthetic appeal, though quartersawn red oak is available on request for the same price. See below for more information on the quartersawing technique.

Soft Maple Acer rubrum, A. saccharinum

A straight-grained, fine-textured wood, soft maple is a hardwood, despite its slightly confusing name. Soft maple, derived from red or silver maple trees, is not as durable as its cousin hard maple, but it more readily accepts stain. Color usually ranges from light cream to pale brown, with occasional dark streaks.

Hard Maple Acer saccharum, A. nigrum

Hard, or rock, maple comes from sugar or black maple trees and is a tough, moderately heavy wood with a fine, uniform texture. Hard maple finishes very smoothly and is extremely durable. Commonly seen with no stain, its natural color varies from nearly white to light tan, sometimes with a reddish tinge.

Cherry Prunus serotina

A dense, even-grained wood, cherry is widely considered to be the finest of the fruitwoods. It is prized for its beauty and is an excellent choice for both formal and casual applications. Natural coloration varies from a light cream to a darker reddish brown. Cherry can darken considerably with age, developing a deep, rich patina over several years.

Hickory Carya spp.

Close-grained and often nearly white in color, hickory is one of the hardest, heaviest, and strongest woods in the United States. Because of its flexibility and resilience, hickory is commonly used in the construction of chairs and other bentwood furniture.

Walnut Juglans nigra

A dense wood, ranging in color from light to deep chocolate brown, the black walnut tree produces one of the finest cabinet woods. Walnut is both slow growing and highly sought after, causing it to be more expensive than many other woods.

Quartersawing Technique

Quartersawing is simply a cutting technique used to achieve a finished appearance different from the more typical flatsawing technique. Quartersawing involves cutting a log into quarters, then cutting boards alternately from the two flat sides of each quarter. The process produces a combination of parallel-line patterns and highly varied figuring that many connoisseurs of fine wood furniture find very appealing. Oak cut in this manner is commonly called tiger oak and is traditionally found in the “Arts & Crafts” style of furniture.

Distinguishing Finish From Wood

Be sure to distinguish finish from wood. For example, “cherry finish” may mean only that a piece of furniture has a reddish stain or a finish similar to cherry wood, even though it contains no real cherry wood. If you’re in the market for solid hardwood furniture, ask for it by name.

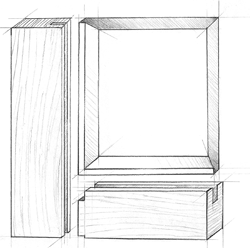

What To Look For When Shopping For Wood Furniture Joinery

The term “wood joinery” refers to the art of making two boards fit together in perfect alignment. Stronger joints generally take longer to construct and require more skill, so the quality of the joinery is often a measure of the quality of the piece of furniture. The following diagram depicts some of the more common methods of wood joinery, some of which are better than others.

What To Look For When Shopping For Wood Furniture Joinery

Look for joints used in the furniture’s construction. If you can’t see a joint, ask for an explanation of how the furniture has been constructed.

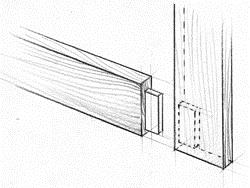

Butt Joint

A weak to moderate joint formed by abutting and gluing two boards together.

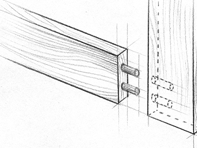

Double Dowel Joint

Much stronger than the butt joint, dowel joints are formed by gluing and inserting dowels into adjoining pieces of wood and then abutting and gluing the boards together.

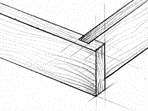

Dado Joint

A strong joint formed by cutting a groove across one board and inserting the adjoining board into that groove.

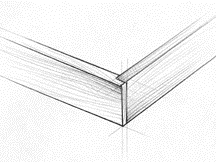

Rabbet Joint

A fairly strong joint formed when two adjoining boards are joined together by notching each of the adjoining boards and overlapping the notched sections, joining them together with glue.

Mortise & Tenon Joint

A very strong joint formed by fitting a peg from one board into a corresponding opening created in the adjoining board. Mortise and tenon joints have been used for centuries in the construction of wood furniture.

Dovetail Joint

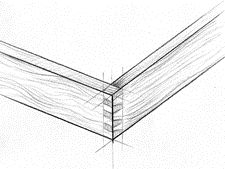

A superior joint formed by creating and gluing a series of interlocking geometric shapes between the adjoining pieces of wood.

French Dovetail Joint

Simply a single dovetail joint that slides into a groove cut into the adjoining piece of wood.

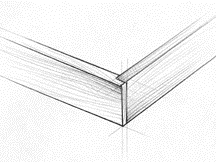

It can be difficult for a buyer to determine the joinery used in a finished piece of furniture. For case goods i.e., cabinets, dressers, and hutches, one of the easiest ways to get an idea of the type of joinery used is to look at a drawer.

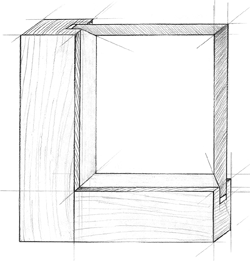

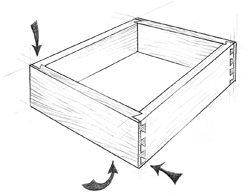

Drawer Construction And Joinery

Perhaps the easiest and best way to get an idea of what kind of quality you are buying is to look at the drawer construction. Open the drawer box, notice the depth of the drawer, what type of drawer glides are used, what material the drawer box is made of, and what method of drawer joinery has been used. Observe how the bottom has been attached, whether the sides of the drawer are made of solid wood or veneer, and if the inside of the drawers have been finished. The best drawers will be constructed with solid wood sides, dovetail joints all four corners, dadoed bottoms, and will be finished on the inside.

Drawers joined using dovetail joints are simply the best and the reason is simple. The glue surface area is increased significantly, and the interlocking geometry of the dovetail joints holds the joint together even if the glue fails. Under normal everyday use, drawers are constantly opened and closed, which puts stress on the drawer front. Dovetail joints hold up extremely well under this kind of constant use. There is no close substitute for dovetailed drawer boxes.

Examining a Drawer

To determine if the drawer is made of solid wood, look at the side of the drawer box. Edge grain should be evident from the exposed end of each board. Find the drawer joints by looking at the corners from the top and the side. Don’t hesitate to ask someone to remove the drawer to allow easier examination.

There are a number of glides and stops used in drawer construction, depending primarily on the size and type of drawer. The glides should operate smoothly without sticking when the drawer is opened or closed and should provide easy access to the full depth of the drawer. They should be strong enough to handle the weight of the drawer when opened fully, and there should be a drawer stop that prevents the drawer from falling out when opened.

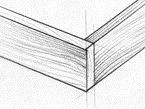

Fit And Finish

Examine the fit and finish of the furniture. The hardware should be straight, doors should close without rubbing, the joints should be tight, and the hinges should be sturdy and durable. The finish should feel smooth and even, with no excess glue or stain present. The furniture should fit together without significant gaps, and all matching pieces should truly match.

What To Look For In Specific Pieces

Case Goods

If you’re shopping for a chest of drawers, dresser, armoire, or a hutch, pay special attention to the sides of the furniture. Avoid lesser quality sides, which are typically made of particle board, plastic laminate, and other inexpensive materials. Instead, look for sides constructed of furniture-grade plywood, solid wood, or frame and panel construction.

Plywood Sides

Solid-core plywood is made up of thin sheets, or plies, of solid wood glued to one another in alternating orientations. This construction method gives plywood some distinct advantages over solid wood in certain types of case goods. It resists warping, swelling, and cracking in fluctuating humidity conditions and can bend more easily for decorative applications. However, plywood is not always as attractive as solid wood and cannot easily be refinished.

Solids Sides

The term “solid sides” means simply that solid planks of wood are glued together to form the wall of a piece of furniture. Solid sides usually finish more consistently than plywood, making them more attractive, and they’re more durable and easier to refinish, making them a better long-term value. Over time, solid wood will expand and contract with humidity changes, but with proper care, no warping or cracking should occur.

Frame and Panel Sides

Frame and panel sides offer the best of both worlds: solid wood without the disadvantage of solid sides. Frame and panel construction involves a solid wood panel “floating” inside a solid wood frame, giving the panel room to shift, expand, and contract with humidity changes. Both flat and raised panels are available. Though more expensive, this construction method is superior for long-term durability and beauty.

Tables and Chairs

Solid wood tables should be finished on the bottom side to block moisture, eliminate warping problems, and keep your clothes from snagging. In addition, for tables with leaves, look for geared guides or heavy duty wood glides. The table should open easily and be sturdy even when the leaves are installed. The leaves should line up evenly with the table top and should fit very securely.

On solid wood chairs, the legs and stretchers should be screwed or pinned as well as glued for added durability with daily use. Wood seats should be solid and comfortable.

Beds

The frames on solid wood beds should attach using quality hardware sufficient to protect the wood and provide stability. Look for heavy duty angle irons on the side rails, as well as wood slats and center supports. The bed should feel solid in its place and should not shake or move easily.

The Look & Feel Of Quality Furniture

As this guide illustrates, perhaps one of the easiest ways to determine the quality of a piece of solid wood furniture is its look and feel. The following is a quick check list of some of the things to look for:

Is it solid wood or veneer?

Is it made of hardwood or softwood?

Where does the wood come from?

Where is the furniture constructed?

What type of joinery has been used in its construction?

Are the drawers constructed using solid wood?

Have the inside of the drawers been finished?

Are drawers constructed using dovetail joints front and back?

Do the drawers have a stop to prevent the drawer from falling out when opened?

Do drawers slide in and out easily?

Is the hardware straight?

Do doors close without rubbing?

Are the joints tight?

Are the hinges sturdy and durable?

Does the finish feel smooth and even?

Are there streaks or is there excess finish or glue present?

Does the furniture fit together without significant gaps?

Do the matching pieces truly match?

If applicable, has frame and panel construction been used?

Have the tables been finished on the bottom side?

Do tables with leaves have geared drives or sturdy glides?

Are tables with leaves sturdy when the leaves are inserted?

Does the table open easily?

Are legs and stretchers on chairs screwed or pinned as well as glued?

Do the leaves fit evenly with the table top and sides?

Do the beds have angle irons and wood slats?

Do the beds feel stable?

Finally, there is no substitute for being a knowledgeable buyer. Do your homework, ask questions and know what you are looking for. Shop around and compare quality and price. Learn as much as you can about the manufacturer of the product. Does the manufacturer have a reputation for quality? Do they stand behind their products? Does the retailer have a good reputation? Remember, this is a long term investment. Take your time, get what you want and know what you are getting.

Follow Us

8509 Davis Blvd.

NRH TX 76182

(817) 514-0372

Showroom Hours:

Tue - Sat, 11-5pm

Extended hours by appointment

Closed Sunday and Monday

Join our email list for a chance to win a $500 gift card! drawings conducted monthly

No Purchase Necessary.

SIGN ME UP!

We respect your privacy and would never sell your personal information.

Contact Us

We will get back to you as soon as possible.

Please try again later.

Copyright ©2022 Woodbine Furniture | All Rights Reserved | Created by Olive + Ash. Managed by Olive Street Design